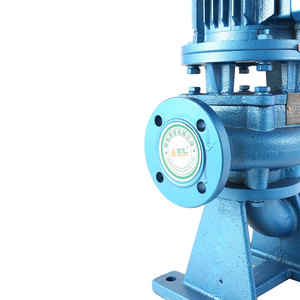

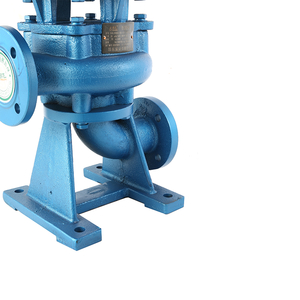

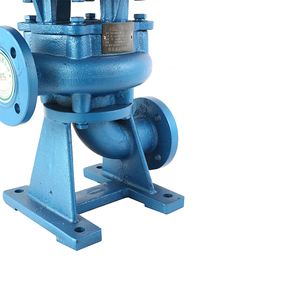

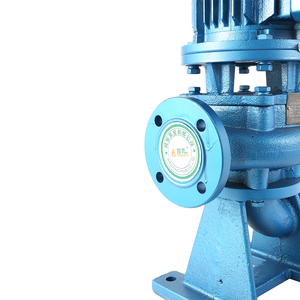

GW series pipe sewage pumps are pumps specially used for discharging sewage, sewage and other liquids. Its performance and advantages are as follows:

1. Efficient: The impeller of GW series pipe sewage pumps adopts non-clogging design, which can effectively avoid pump clogging and ensure efficient operation of the pump.

2. Energy saving: the pump adopts a high-quality energy-saving motor, which can effectively reduce the energy consumption of the pump and save energy.

3. Reliable: The sealing performance of GW series pipe sewage pumps is very good, which can effectively prevent the pump from leaking and improve the reliability of the pump.

4. Compact structure: The design of the pump is very compact, small in size and light in weight, which is convenient for installation and maintenance.

5. Long service life: The pump is made of high-quality materials, has good corrosion resistance and wear resistance, and has a long service life.

6. Wide range of applications: GW series pipe sewage pumps are suitable for discharging sewage, sewage and other liquids, and are widely used in municipal engineering, construction sites, factories, hospitals, hotels and other places.

In a word,

GW series pipe sewage pumps have the advantages of high efficiency, energy saving, reliability, compact structure, long service life and wide application range, etc., it is a very excellent sewage pump.

GW series pipe sewage pumps product use:

GW series pipe sewage pumps are special pumps for discharging liquids such as sewage and dirt, and are suitable for the following occasions:

1. Municipal engineering: It can be used in municipal sewage stations, sewage treatment plants, municipal engineering construction, etc.

2. Construction site: It can be used for construction site sewage, drainage, rainwater drainage, etc.

3. Factories, hospitals, hotels and other places: it can be used for the discharge of industrial sewage, hospital sewage, hotel sewage and other occasions.

4. Port wharf: It can be used for ship sewage, wharf sewage, etc.

In short, GW series pipe sewage pumps are suitable for occasions where liquids such as sewage and sewage need to be discharged, which can effectively improve the discharge efficiency and quality, and ensure environmental sanitation and ecological health.

The installation and use of GW series pipe sewage pumps need to pay attention to the following points:

1. Before installation, check whether all parts of the pump are in good condition and whether there are sundries in the pump body.

2. Before installation, check whether the power supply voltage meets the requirements, and ensure that the phase and frequency of the power supply and the motor are consistent.

3. Pay attention to the positioning and level adjustment of the pump during installation to ensure that the foundation of the pump is stable and the inlet and outlet of the pump are firmly connected with the pipeline.

4. After the installation is completed, a no-load test run should be carried out, and it will be used formally after confirming that there is no abnormality.

5. During use, it should be used according to the rated parameters of the pump, and it should not be overloaded to ensure the performance and life of the pump.

6. During use, attention should be paid to check the sealing performance of the pump, and the sundries and dirt in the pump body should be cleaned in time.

7. When you stop using it, you should cut off the power first, and then close the water inlet and outlet valves of the pump to avoid idling of the pump and backflow of water.

In short, the installation and use of

GW series pipe sewage pumps need to pay attention to various details to ensure the performance and life of the pump, while ensuring safety and environmental protection during use. If necessary, follow the relevant installation and use instructions.

Español

Español

Catalogue

Catalogue